The Evolution of Tubing Inspection Technologies - More Coils Means Better Data

- Jon R. Konerza

- May 22, 2016

- 2 min read

Sunday May 22, 2016

Technologies throughout our world have evolved at an ever increasing rate. Tubing inspection technology is no exception to this. Over the last 3 to 5 years we have experienced a dramatic change in the quality and type of tubing inspection data collected. For the past 20 to 30 years, Eddy Current has typically been referred to as a “black magic” inspection technique, mostly because of the complexity of the signals to analyze. Unless proper training is involved, this data can be quite difficult to understand. Like the ultrasonic shear wave inspection technique, unless you are performing this type of inspection on a daily basis, it is very easy to forget or lose the knowledge on how to properly employ the technology and accurately analyze the data.

Eddy Current Technology (ECT) has evolved into the Eddy Current Array (ECA). The difference between these two technologies is in the amount of coils designed within the probe body. Most off-the shelf probes are designed with a standard set of coils which interrogate the entire circumference of the tube at one time.

This style is referred to as a bobbin coil winding. While this probe is still very reliable for general purpose inspections, it does have limitations (e.g. circumferential crack detection, defect averaging, less sensitivity to flaws at tube to tube sheet interfaces, etc.).

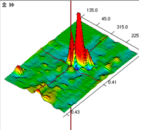

Eddy Current Array (ECA) probes have been designed to have anywhere from 16 coils to 48 coils, each individually interrogating the tube circumference. This technology allows the ability to detect and accurately size flaws in the circumferential or axial directions, while displaying the data in c-scan and isometric (3D) views. This makes it easier for the analysts to identify where the flaws are located, circumferential extent, characteristics of flaws, and sizing. ultimately helping to properly identify what type of damage mechanisms are occurring within the heat exchanger tubing.

This technology is still highly operator dependent and is limited to alloy tubing (stainless, titanium, inconel, etc). At Sentinel Integrity Solutions, we are utilizing this technology as either a stand-alone inspection or as a prove up technique, to help characterize, size, and determine the relevancy of defects.

In future articles we will discuss advances in Air Cooler inspections (NFT, NFA, MFL & IRIS), as well as new inspection techniques for carbon steel weld inspections, CUI, and corrosion under fireproofing inspections.

Comments